Kitchen Remodeling: A Comprehensive Planning Guide

From Vision to Budget: Defining Scope and Priorities

Outline of the article you’re about to read:

– Scope, vision, and budget fundamentals

– Layout and workflow: triangle vs. zones, ergonomics, accessibility

– Materials and finishes: durability, maintenance, sustainability

– Systems and services: electrical, lighting, plumbing, ventilation

– Timeline, permits, hiring, risk control, and a practical conclusion

Every memorable kitchen begins with a clear decision: what problem are you solving? More prep space, better storage, safer circulation, or a brighter, calmer mood? Before you compare tile or debate hardware finishes, write a brief project mission. One or two sentences can anchor hundreds of decisions: “Create a durable, easy‑to‑clean kitchen that supports weeknight cooking and weekend baking for four.” Then translate that mission into scope. Are you replacing surfaces only (refresh), changing layout within existing walls (pull‑and‑replace), or moving walls and utilities (full remodel)? Scope determines budget, permits, timeline, and how much your daily routine shifts during construction.

Cost planning works best when it’s both realistic and flexible. Regional costs vary, but a mid‑range remodel commonly lands in the four to five figures per major component, while full renovations can reach into the six‑figure territory for larger spaces. A practical starting allocation is:

– Cabinets: 25–35%

– Appliances: 10–20%

– Countertops: 10–15%

– Flooring/backsplash/paint: 5–15%

– Mechanical/electrical/plumbing: 10–20%

– Labor and permitting: 20–35%

– Contingency: 10–20%

To test priorities, draft two lists: must‑haves and nice‑to‑haves. Must‑haves are non‑negotiable safety or function items (adequate lighting, GFCI‑protected outlets, vented hood, durable worktops). Nice‑to‑haves add personality or convenience (apron‑front sink, under‑cabinet lighting, pull‑out trays). When costs rise, trim from the second list first. A simple scenario illustrates this: in a 12×15 kitchen, upgrading cabinet boxes from particleboard to plywood may add a low four‑figure sum but dramatically improve longevity; pairing that with a modest countertop selection can keep the total stable. The guiding principle is tradeoffs, not sacrifice. Think like a chef: you season the plan in layers—function, durability, and then style—so the result tastes right without blowing the budget.

Layout and Workflow: Ergonomics, Clearances, and Accessibility

Layouts shape comfort as much as aesthetics. The classic “work triangle”—the path between cooktop, sink, and refrigerator—aims for a total distance of roughly 13–26 feet with each leg between about 4–9 feet. This encourages efficient movement while avoiding crowding. Modern households, however, often cook together or combine cooking with homework, coffee service, and entertaining. That’s where zone planning shines: define prep, cook, clean, bake, beverage, and storage zones, then assign landing spaces and tools to each. The goal is to reduce cross‑traffic and keep messy tasks from interrupting serving and seating.

Clearances matter. Common guidelines include:

– Aisle width: 42 inches for one cook, 48 inches for two

– Island spacing: at least 36 inches for tight spaces, 42–48 inches preferred

– Door swings: avoid conflicts; consider pocket or sliding doors for pantries

– Countertop landings: 15 inches near refrigerator, 12–18 inches beside cooktop, 15 inches near oven

– Seating overhangs: 12 inches for counter height, with sturdy knee space

– Vent hood height: typically 24–30 inches above the cooktop, depending on fuel and manufacturer guidance

Choose a layout that fits the shell you have. Galley kitchens excel in small spaces with parallel runs and short travel distances. L‑shaped plans free a corner for casual dining. U‑shaped layouts maximize storage and uninterrupted prep. Islands work when circulation remains at or above 42 inches, while peninsulas can create a social boundary without requiring full perimeter clearance. For accessibility, consider:

– A 60‑inch turning circle where possible

– Variable counter heights (for seated prep at ~30–34 inches)

– Pull‑down shelves and D‑shaped hardware

– Drawer‑based base cabinets to reduce bending

– Contrasting edge colors for visual clarity

By sketching traffic paths and placing tasks where they naturally flow—rinse produce near the sink, prep between sink and cooktop, trash and compost within a step of both—you turn chaos into choreography. A simple tape‑on‑floor mockup can reveal pinch points before you commit. Think of it as a dress rehearsal: if the movement feels natural now, it will feel even better once the lights, finishes, and aromas come alive.

Materials and Finishes: Durability, Maintenance, and Sustainability

Materials are the workhorses of daily life. Cabinets form the backbone: plywood boxes resist sag and moisture better than particleboard; frameless construction maximizes interior space; soft‑close hardware protects doors and fingers. For door styles, slab profiles create a clean, contemporary line, while shaker‑style frames offer timeless simplicity. Finishes influence upkeep—painted surfaces look crisp but show wear sooner; stained wood hides dings; thermofoil is budget‑friendly but sensitive to prolonged heat.

Countertops set the tone for prep and cleanup. Quartz composites deliver consistent color, excellent stain resistance, and low maintenance. Natural stones like granite and soapstone provide unique movement and heat tolerance, though some require periodic sealing. Butcher block is warm and repairable with sanding, yet it demands regular oiling and vigilance against standing water. Solid surface offers inconspicuous seams and integral sinks; stainless steel is hygienic and heat‑proof but shows scratches that develop into a matte patina. A typical installed cost hierarchy runs from laminate at the lower end, through wood and tile, into mid‑range solid surface and engineered stone, with select natural stones occupying higher tiers. Choose with your habits in mind: frequent baking benefits from cool, smooth slabs; heavy frying calls for easy‑clean surfaces near the range.

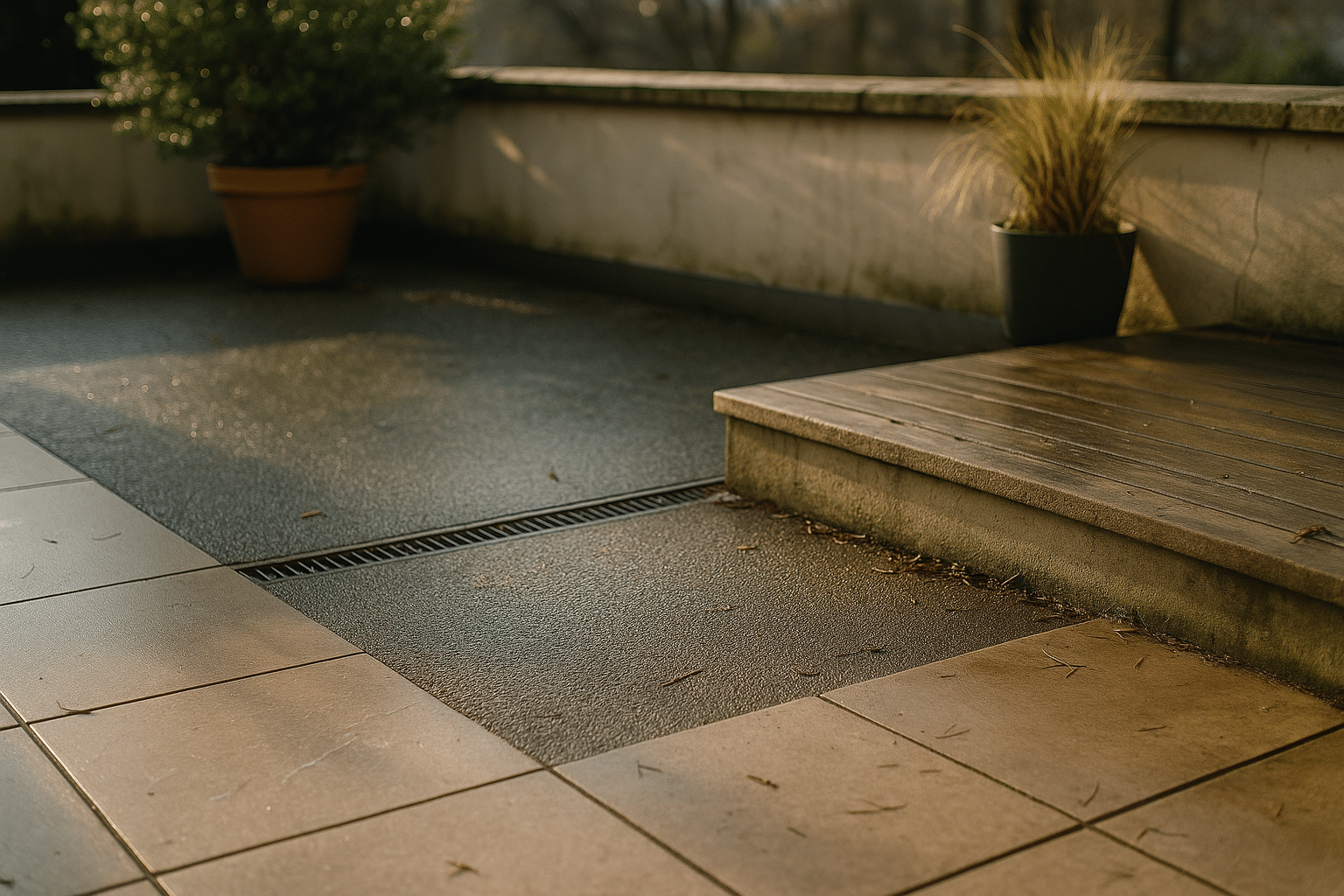

Flooring must balance resilience and comfort. Porcelain tile is dense and highly water‑resistant, ideal for splash zones; larger formats reduce grout maintenance. Engineered wood softens acoustics and adds warmth; choose a durable finish and mind water exposure. Luxury vinyl planks offer water resistance and forgiving installation over varied subfloors. Cork provides cushion underfoot and moderate sound absorption, yet needs a protective finish. For backsplashes, ceramic tile remains a versatile staple; glass tile reflects light; stone slabs minimize grout lines; stainless panels behind a range simplify cleanup.

Sustainability weaves through every choice:

– Low‑ or zero‑VOC paints and finishes improve indoor air quality

– Formaldehyde‑free plywood and certified wood support healthier cabinets

– Recycled content countertops (glass or composite) reduce resource extraction

– LED lighting cuts energy use; warm 2700–3000K tones feel inviting

– Water‑saving faucets and efficient dishwashers trim utility bills

Think lifecycle. A slightly higher upfront cost for robust hinges, moisture‑resistant boxes, and durable counters can outlast multiple repainting cycles. Pick a cohesive palette—two cabinet tones, one primary counter, and a backsplash that bridges them—to avoid visual clutter. Like a well‑edited recipe, fewer strong ingredients often yield a more satisfying, calm space.

Systems and Services: Electrical, Lighting, Plumbing, and Ventilation

A beautiful kitchen still fails if outlets are scarce, lights glare, or steam lingers. Start with electrical. Many jurisdictions require at least two 20‑amp small‑appliance circuits for countertop receptacles, spaced so no point is more than 24 inches from an outlet and typically within 4 feet of each other along the run. Use GFCI protection for countertop zones and laundry‑adjacent sinks; combination AFCI protection may be required on branch circuits—verify locally. Provide dedicated circuits where practical for refrigerator, dishwasher, disposer, microwave, and any high‑draw ovens or cooktops; electric ranges often need a 240‑volt circuit rated around 40–50 amps, depending on equipment. Plan for under‑cabinet lighting feeds and island outlets early to avoid visible cords or tricky floor penetrations.

Light in layers to eliminate shadows and hotspots:

– Ambient: recessed or low‑profile fixtures for overall illumination

– Task: under‑cabinet bars or pucks aimed at the front of the counter

– Accent: toe‑kick or cabinet interior lighting for depth and mood

– Color quality: aim for 90+ CRI where possible; choose 2700–3000K for warm, food‑friendly tones

– Dimming: separate controls for zones let you shift from prep‑bright to dinner‑soft

Plumbing deserves equal foresight. Group wet zones (sink, dishwasher, beverage faucet) to minimize pipe runs and simplify venting. Standard practice maintains a drain slope near 1/4 inch per foot to avoid clogs. Include dedicated shut‑offs for all fixtures and stainless supply lines for durability. If relocating the sink, confirm structural feasibility for new vents and consider a loop vent only where locally permitted. A modest hot‑water recirculation loop can reduce wait times in long runs. For water quality, under‑sink filtration or a whole‑house system can be planned during rough‑in to conceal equipment neatly.

Ventilation keeps grease and moisture out of the air and off your cabinets. A ducted hood is typically more effective than recirculating filters. Size the hood by output and coverage: a common rule is about 1 CFM per 100 BTU for gas equipment, or roughly 100 CFM per linear foot for electric cooktops. Ensure the capture area fully overlaps front burners. Short, straight duct runs perform better; prefer smooth metal duct, minimal bends, and exterior termination with a backdraft damper. In tighter homes, high‑capacity hoods may require make‑up air to keep pressure balanced. Plan it now; enjoy fresh, quiet air later.

Conclusion: Timeline, Permits, Hiring, and Risk Control

Remodels run on schedules and expectations. A typical sequence looks like this:

– Design and budgeting: 2–6 weeks for measurements, drawings, selections, and quotes

– Ordering lead times: cabinets 4–10 weeks; specialty counters 1–3 weeks after template; fixtures and lighting 1–3 weeks

– Permits and approvals: 1–4 weeks depending on scope and locality

– Demolition and framing: 1 week for moderate projects

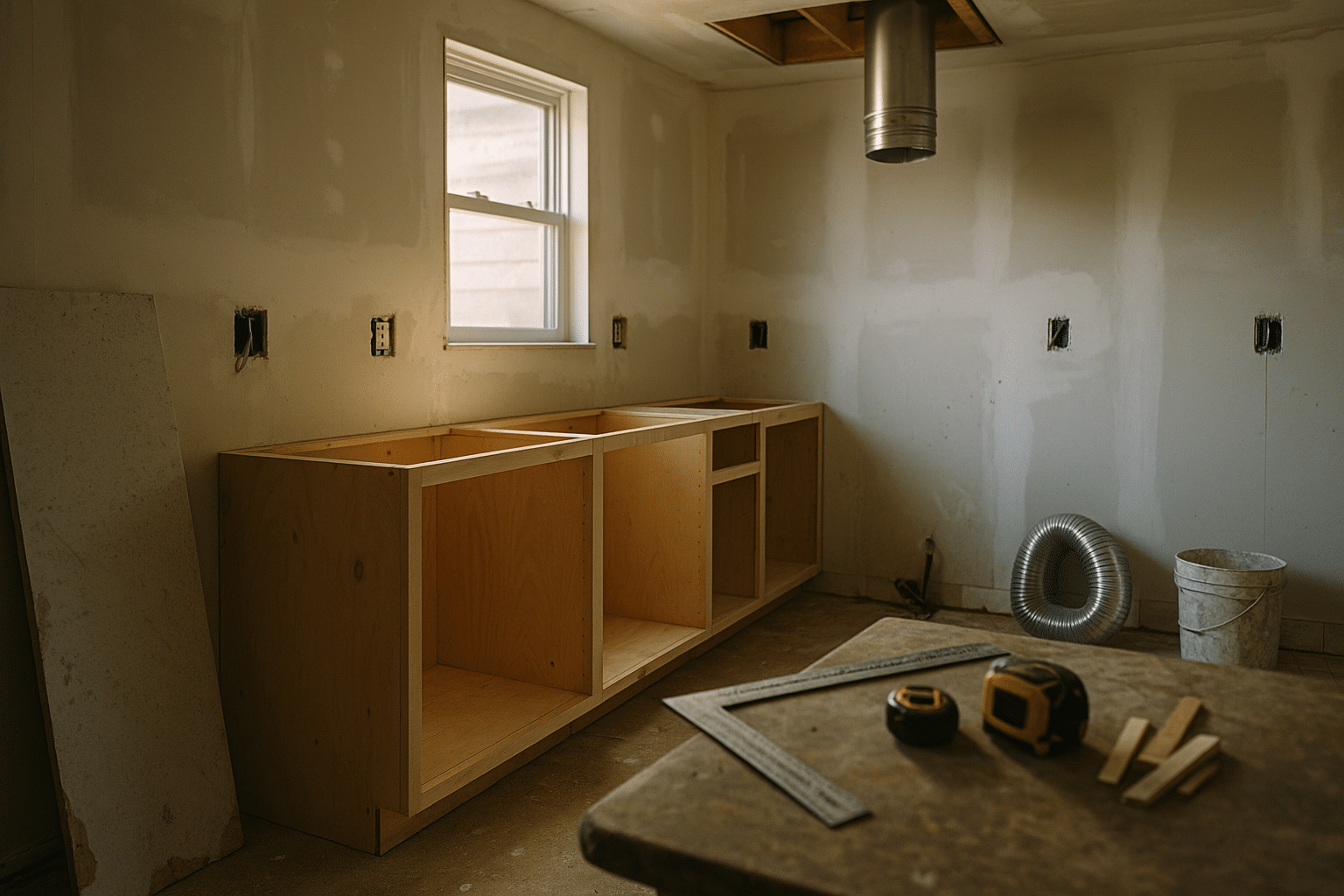

– Rough‑in (electrical, plumbing, HVAC): 1–2 weeks

– Inspections: interspersed; factor a few days’ float

– Drywall, priming, and paint: 1–2 weeks

– Flooring, cabinets, and trim: 1–2 weeks

– Countertop template and install: template after cabs set; install 1–2 weeks later

– Backsplash, final fixtures, and punch list: 1–2 weeks

Permits protect safety and resale value. Electrical and plumbing changes often require them; structural modifications almost always do. Assemble a packet with floor plans, elevations, fixture locations, and a simple scope narrative. Inspections are checkpoints, not roadblocks—schedule them proactively and keep the site tidy for quick sign‑offs. If an inspector flags something, treat it as a quality upgrade for your future self.

Choosing the team is part due diligence, part chemistry. Seek at least three bids with a common scope so comparisons are meaningful. Ask for proof of license and insurance, plus two recent references whose projects resemble yours. Read contracts carefully:

– Clear payment schedule tied to milestones, not arbitrary dates

– Defined allowances for fixtures and finishes

– Change order process with written approval and documented costs

– Start and substantial‑completion targets with reasonable float

Expect surprises—hidden plumbing, uneven subfloors, or outdated wiring. Manage risk with a contingency of 10–20%, daily site photos, and a single source of truth for decisions (a shared checklist or binder). Store materials indoors to acclimate; inspect deliveries on arrival; label boxes by room and wall for smooth installation. Finally, close with a punch list: test every outlet and GFCI, run each faucet, align doors and drawers, seal stone, caulk splash edges, and collect manuals. When the last painter’s tape lifts, you’ll have more than a new room—you’ll have a kitchen tuned to how you live. Plan with empathy for your future routines, and the space will return the favor every day.