Learn more about Irrigation Control

Outline:

– Fundamentals: water balance, soil properties, climate signals, and how they drive irrigation decisions.

– Technology: controllers, valves, sensors, and flow measurement with practical pros and cons.

– Design & zoning: matching application methods to plants, pressure, slopes, and microclimates.

– Scheduling: ET-based methods, cycle-soak, runtime math, and seasonal adjustments.

– Maintenance, troubleshooting, ROI, and a forward-looking conclusion.

Irrigation Control Fundamentals: Water, Soil, and Climate

Irrigation control starts with a simple truth: plants need a steady, not constant, supply of water. The controller, sensors, and valves are only as effective as the understanding behind them. Picture soil as a quiet reservoir, roots as carefully placed straws, and the atmosphere as a gentle thief. Your job is to keep that reservoir within a healthy range—neither spilling over nor running dry—by pacing applications to match demand. That demand is governed largely by evapotranspiration (ET), the combined water loss from soil evaporation and plant transpiration.

Think of the water balance as a weekly ledger: change in soil storage equals inputs minus outputs. In words: storage increases with irrigation and rainfall, and decreases with ET, runoff, and deep percolation. For many landscapes, ET can range roughly from 0.05 to 0.25 inches per day depending on season, wind, and sun exposure. Soil texture determines how much water that “ledger” can hold. Typical available water capacity per foot of soil depth is often around: sandy soils 0.5–1.0 inches, loams 1.5–2.0 inches, and clays 2.0–2.5 inches. Rooting depth varies by species and maintenance, which means two beds side by side can have different refill points.

Key variables to track include:

– ET: daily atmospheric demand, often estimated from weather data and crop/landscape coefficients.

– Soil texture and structure: they set both storage capacity and infiltration rate.

– Root depth: defines the size of the usable reservoir.

– Microclimate: shade, wind, and reflected heat change water needs.

– Slope: can convert overwatering into runoff rather than infiltration.

Control decisions are more resilient when grounded in these fundamentals. If a loam-based turf area has an effective root zone of six inches, it might hold around three-quarters to one inch of plant-available water. If midsummer ET averages 0.15 inches per day, the practical refill interval could be four to six days—shorter if hot winds arrive, longer if cloud cover lingers. This approach turns irrigation from guesswork into responsive care, aligning timing and volume with a living system that changes week to week.

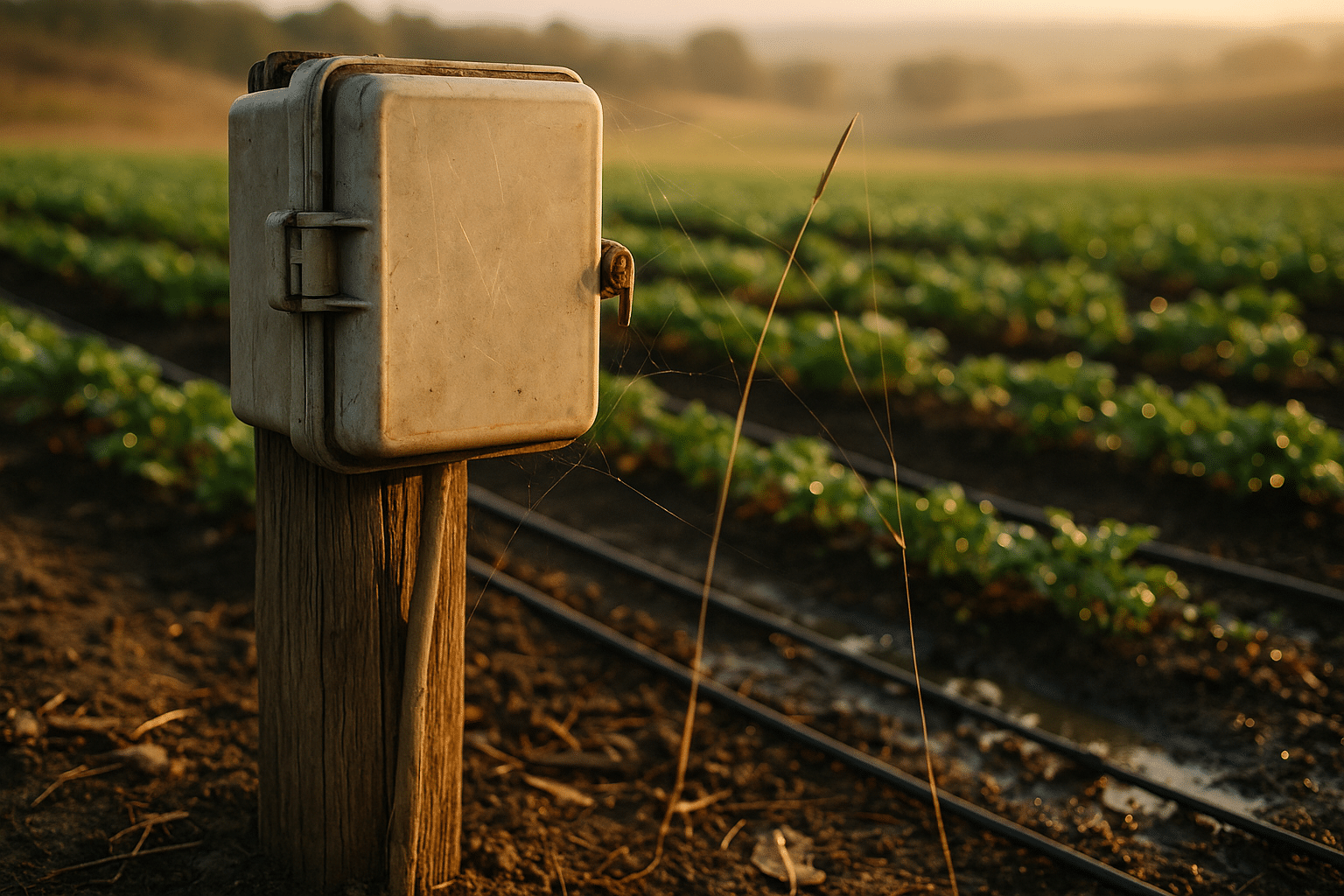

Technologies That Make Control Possible: Controllers, Valves, Sensors, and Flow

Modern irrigation control blends simple mechanics with data-driven adjustments. At the core is a controller that decides when and how long to water. Basic timers run fixed days and durations, which can be reliable but inflexible across seasons. Weather-aware controllers add ET or rainfall inputs to reset schedules automatically, helping prevent water waste during cool spells and dry gaps after heat waves. Soil moisture-based approaches trigger watering only when the root zone drops below a threshold, a logic that mimics how skilled growers irrigate by feel—only with silicon instead of fingertips.

Valve and flow hardware round out the system. Electric valves with pressure regulation maintain consistent output to sprinklers or emitters. Flow sensors measure actual water movement and can shut the system down when unexpected usage appears. That single signal can prevent hours of unnoticed leakage. In many field reports and utility program summaries, weather-responsive control has been associated with roughly 20–40% water savings, and soil moisture-based systems have shown savings commonly in the 15–30% range, depending on site conditions and user setup. Real results vary—good design and tuning matter as much as the device itself.

Sensor options differ in how they “see” water:

– Rain and freeze sensors: simple on/off protections for stormy or cold conditions.

– Soil moisture probes (capacitance, TDR, or tensiometers): they infer or measure water status at specific depths.

– Flow meters: verify that what the schedule asks for is actually what is delivered.

– Weather inputs: on-site stations or trusted local data to compute ET and adjust run times.

Comparisons help choose wisely. Fixed timers are inexpensive and predictable but require manual seasonal changes. Weather-driven control is hands-off once configured, but needs accurate local data and occasional calibration. Soil-based control can be highly responsive to micro-sites, but proper sensor placement is crucial—install too shallow and you’ll chase surface evaporation; too deep and you may miss stress at active root depths. A balanced approach often layers weather adjustments for broad seasonal trends with soil sensors for zone-specific reality checks, all overseen by flow monitoring to catch anomalies.

Design and Zoning: Matching Application Methods to Site Realities

Control is only as good as the plumbing and emitters downstream. Sprays, rotors, bubblers, and drip lines each deliver water differently. Sprays typically apply higher precipitation rates (often around 1.5–2.0 inches per hour), making them suitable for small areas but more prone to runoff on slopes or compacted soils. Rotors apply more slowly (commonly 0.4–0.7 inches per hour), which can increase infiltration and uniformity over larger turf. Drip distributes water at the soil surface or below, delivering directly to root zones while minimizing evaporation and overspray.

Hydrozoning—grouping plants with similar water needs and sun exposure onto the same valve—simplifies control. Mixed beds of succulents and high-demand ornamentals often end in compromise and waste. Better to separate them so each receives appropriate timing and volume. Pressure regulation and filtration are equally important. Sprays and rotors benefit from consistent pressure to maintain matched precipitation rates, while drip requires filtration to protect emitters from clogging and pressure compensation to keep application uniform across long lateral runs.

Practical design checks include:

– Coverage: aim for head-to-head overlap with sprays and rotors to avoid dry arcs.

– Application rate vs. soil intake: adjust to stay below infiltration capacity, especially on slopes.

– Uniformity: strive for a high distribution uniformity so runtimes aren’t inflated to fix dry corners.

– Pipe sizing: avoid excessive velocity that creates pressure loss and water hammer.

– Valve loading: keep flow within recommended ranges to maintain stable operation.

Comparisons by site type clarify choices. Tight courtyards with odd corners often benefit from drip or micro-sprays to avoid overspray onto walls and paths. Large open turf areas tend to fare well with rotors for even, slower application and fewer zones. Sloped ornamental beds respond best to drip or to cycle-soak strategies with sprays. When design respects physics, control becomes straightforward: set runtimes to meet plant demand, confident that delivered water is uniform, infiltration-friendly, and free from avoidable losses.

Scheduling and Optimization: From ET to Runtime and Seasonal Adjust

Scheduling is where knowledge becomes action. A common approach uses ET to estimate how much water the landscape lost since the last irrigation, then replaces a portion of that based on plant type and acceptable stress. The water budget method combines precipitation rate (how much your system applies per hour) with the irrigation need (inches). A practical formula often used to approximate precipitation rate for spray/rotor zones is: PR ≈ 96.3 × total GPM ÷ area (square feet). Once you know PR, runtime is simply irrigation need divided by PR, adjusted for efficiency and distribution uniformity.

To tame runoff and improve infiltration, break long runtimes into cycle-soak segments. For example, instead of 24 minutes straight on a slope, you might run three cycles of eight minutes separated by short soak periods. Seasonal adjustment fine-tunes schedules as weather shifts. Many sites run summer baselines at 100% and dial back to 50–70% in spring and fall, with deeper reductions in cool, wet winters. Wind and heat waves call for short-term corrections: watering earlier in the morning and adding a small bump to compensate for elevated ET without flooding the soil.

Useful optimization habits include:

– Verify PR: measure can-catchments to compare real output with design estimates.

– Apply a scheduling coefficient when uniformity is modest, but investigate fixes.

– Shift start times to early morning to reduce evaporation and wind drift.

– Use rain/soil signals to skip cycles during cool or wet periods.

– Track changes: note adjustments and outcomes to refine next season’s plan.

Comparing strategies reveals trade-offs. Strict ET-based schedules are systematic and scalable across many zones but can miss localized dry spots without feedback. Soil-triggered schedules excel in microclimates but require sensible thresholds and periodic recalibration as roots deepen or mulch thickness changes. A combined method—ET for the broad strokes, soil feedback for fine detail, and cycle-soak to respect infiltration—keeps water where it belongs: in the root zone, at the right time.

Maintenance, Troubleshooting, ROI, and Conclusion: Sustaining Smart Irrigation Control

Even thoughtful schedules fail when hardware drifts out of spec. A brief monthly walk-through often pays for itself. Look for misaligned nozzles, sunken heads, broken drip fittings, weeping valves, and clogged filters. Check zone pressures with a gauge to confirm regulators are doing their job. If equipped, review flow logs for off-hours usage that hints at leaks. Before the first freeze, winterize exposed components to prevent cracks. After major landscape changes, revisit hydrozones—new plantings and shade patterns can shift water needs considerably.

A focused maintenance plan can be simple:

– Monthly: visual inspection, quick nozzle clean, controller memory check.

– Quarterly: filter flushes, pressure verification, sensor calibration.

– Seasonally: schedule resets, valve box cleaning, test rain/soil/flow devices.

– Annually: audit distribution uniformity, verify precipitation rates, update maps.

Return on investment improves when savings meet or beat equipment costs. Consider a property using 300,000 gallons in a warm season at an all-in water/sewer cost near $0.01 per gallon. A 20% reduction saves about 60,000 gallons, or roughly $600. If upgraded control and sensors cost $800–$1,200 installed, a one- to three-season payback is plausible, particularly where water rates or drought surcharges are higher. Flow shutoff features can also avert costly damage; a single prevented mainline break or stuck valve during a vacation can justify the upgrade.

For homeowners, facility managers, and growers, the path forward is clear: pair sound design with responsive control and steady maintenance. Start with fundamentals and measure what matters—ET, precipitation rate, and uniformity—so your adjustments are grounded in evidence, not guesswork. Layer in weather inputs, soil feedback, and flow verification to catch problems early. Finally, celebrate the quiet wins: fewer runoff streaks on sidewalks, healthier roots, and bills that trend down instead of up. Irrigation control, done thoughtfully, turns water into a precise instrument—steady, efficient, and tuned to the living systems you care for.